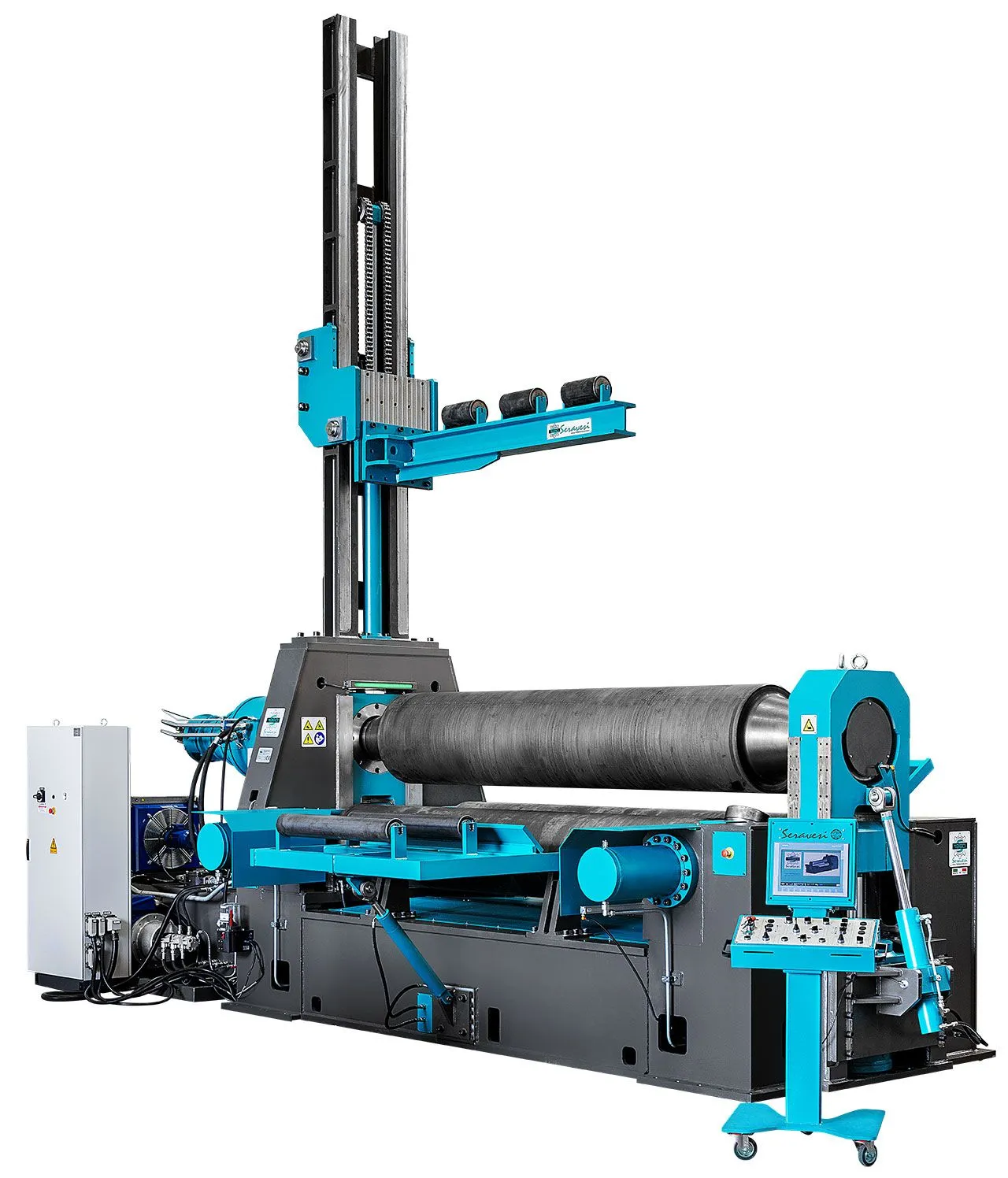

The E79 is a hydraulic 3 roll Plate Roll bending machine with Variable Axis, 3 Roller Bending Machine composed of bottom rolls on horizontal axis and a top motorised roll with hydraulic vertical movement.

The E79 series bending machines are available with a capacity from 25mm to 300mm and roll length from 1000mm to 6000mm.

obtained is excellent thanks to the high push of the top roll which is used in this phase as a bending press.

of its geometry: In fact, the bottom rolls move horizontally and are independent from one another with variable pitch, whilst the motorised top roll moves vertically.

Oil Platforms

Marine Industry

Reactors and Turbine

Boiler

Earth Moving Machines

Tank for Trucks

Crossbeams made of electro-welded steel, subjected to normalising heat treatment.The supporting frames of the rolls’ movement cylinders are made of electro-welded steel and are subjected to normalising heat treatment.Rolls made of forged and tempered special alloy steel or carbon steel.

– Upper motorised roll with epicyclic reduction gear and hydraulic motor.

– Side rolls with automatic brake system to prevent the plate from slipping;Linear potentiometers fitted on each roll (two on each roll) that allow electronic control of parallelism between rolls.Radial bearings fitted on all rolls, self-aligning as double row SKF or FAG branded barrel bearings.Two pumps or up to six for the bigger sizes for maximum linear and rotational thrust. Having a system with more pumps always produces simultaneous movements, including the possibility of both rotating and pressing up to the maximum capacity. In the event of pump failure, the machine can also be operated even if the performance is reduced.The cylinders are made of alloy steel and carbon steel with a chrome-plated rod and use seals from the primary brands.Hydraulic control unit consisting of: motor pump unit, electro valves, pressure relief valves which guarantee overload protection.Hydraulic opening handles to allow the produced tube removal in horizontal position.Automatic centralised lubrication system with a pump which has an autonomous tank, programmable from the touch panel.Siemens, ABB, Telemecanique, Moeller electrical system. It consists of a mobile console control panel connected to the machine with low voltage and a general cabinet where there are all of the other electrical components, as well as the machine control PLC SIEMENS S7.Independent SIEMENS KTP1200 PN control Touch Panel with a 12” touch screen colour display. By changing pages it is possible to see on the display the position, the balance of the rolls, to setup and read the tilting of the rolls, to set their speed (two rotation speeds), the diagnostic functions and machine alarm.Modem to remotely control the PLC in the event of software changes and resolution of machine faults.Air or water cooling system for hydraulic oil.

3 Rolls Plate Bending Machine

3 Rolls Plate Bending MachineIf you are interested in receiving information about our products fill out the form on the side.