roll benders, also known as a roll bending machine, roller bender, is a machine used to bend metal sheets, plates, and profiles into cylindrical or conical shapes. roll bending machine, plate roll, tube bender, metal forming, roll bending process, roll bender types

- What is a Roll bender?

- Uses of Roll benders?

- Types of Roll benders?

- What are the advantages and benefits of Roll benders?

- Manufacturing Process of Roll benders?

- Applications of Roll benders?

- How to choose the right Roll bender?

- Maintenance tips for Roll benders?

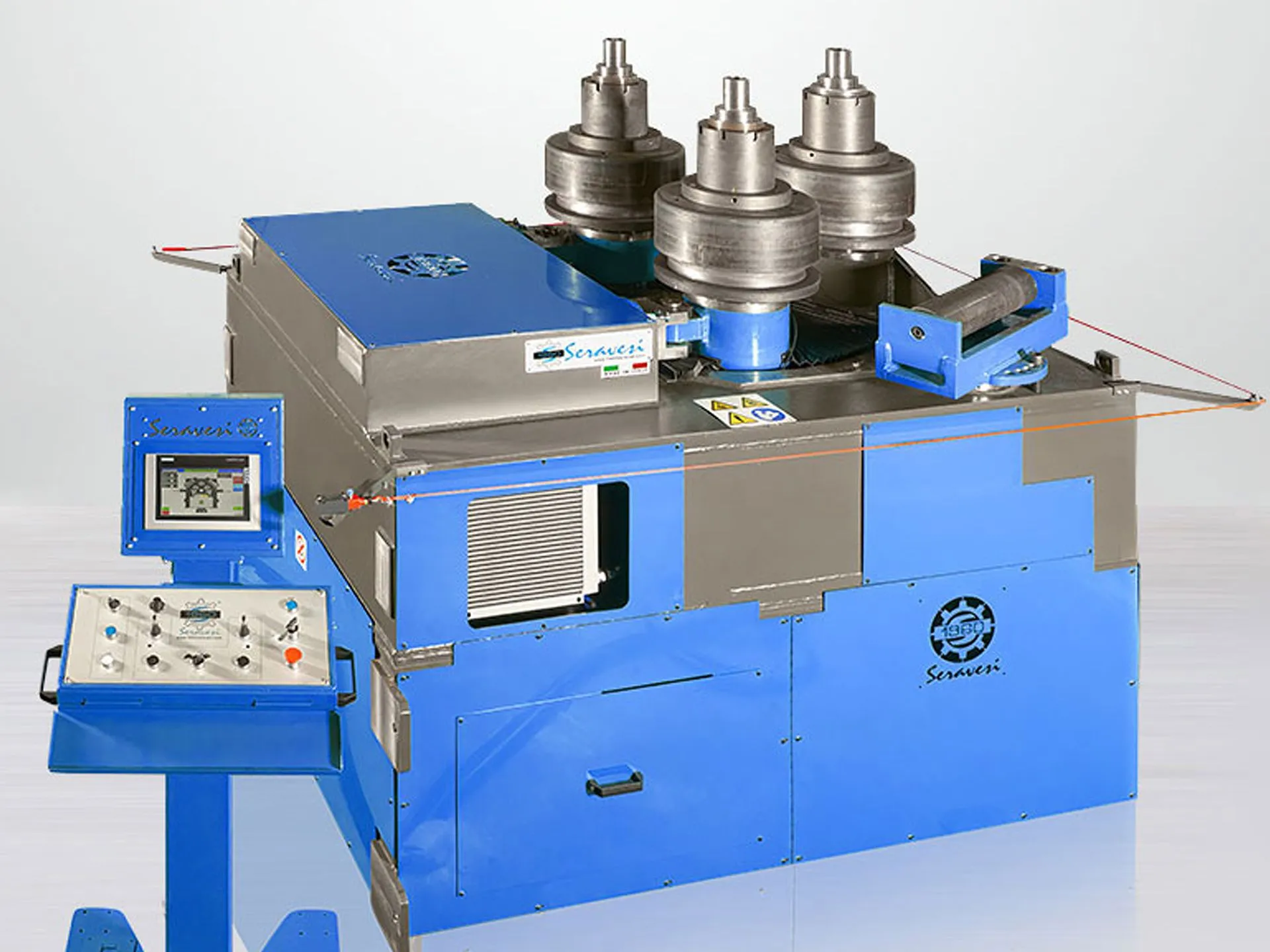

What is a Roll bender?

A roll bender (also called a roll forming machine or plate roll) is a mechanical device used to bend metal plates, sheets, or tubes into curved shapes by passing the material between two or more rotating rolls. Instead of bending with a single die, roll bending achieves gradual curvature: the workpiece is fed through progressively adjusted rolls so that elastic and plastic deformation combine to form a smooth, consistent radius. This makes roll benders ideal for tasks that require large radii, continuous curves, or cylindrical shapes where a press brake or stamp would be inefficient or leave visible marks.

Uses of Roll benders?

Roll benders are used wherever controlled, repeatable curvature of metal is needed. Common uses include forming large-diameter pipes and cylinders, creating curved architectural panels, shaping guardrails, and manufacturing components for tanks and pressure vessels. In shipbuilding and heavy fabrication, roll benders shape hull plates and structural rings; in HVAC and ductwork they form circular ducts and fittings. Beyond heavy industry, smaller roll benders are used in artistic metalwork and furniture to produce neat, continuous curves without the deformation lines typically produced by other bending methods.

Types of Roll benders?

There are several types of roll benders tailored to different materials and jobs. Three-roll plate rolls are common in sheet metal work: two lower rolls support the sheet while an adjustable top roll applies pressure to bend. Four-roll machines add control and reduce springback by allowing symmetric bending. For tubes and pipes, mandrel roll benders include internal supports (mandrels) to prevent ovalization and produce tight-radius bends. Specialty configurations such as section benders or profile roll machines handle structural shapes like I-beams or T-profiles. Manual, hydraulic, and fully CNC-controlled roll benders are available, differing in automation, precision, and throughput.

What are the advantages and benefits of Roll benders?

Roll bending offers distinct advantages compared to other bending methods. First, it produces smooth, continuous radii without sharp transitions or tool marks, which improves both aesthetics and structural integrity. Second, roll benders handle large workpieces and long radii efficiently, where press brakes or stamping presses would struggle or be impractical. Third, modern roll benders—especially CNC models—deliver high repeatability and tight tolerances, reducing scrap and rework. The process also spreads strain over the length of the part, minimizing local thinning. Finally, with options for mandrels and variable roll positioning, roll benders can be adapted for complex profiles, tight radii, and materials that are prone to springback.

Manufacturing Process of Roll benders?

The manufacturing of a roll bender combines mechanical engineering, precision machining, and hydraulic/electrical systems integration. The primary structural frame is typically fabricated from heavy steel plates and welded assemblies to withstand rolling forces. High-precision rolls are turned from alloy steel and ground to exact diameters; rolls may be chromium-plated for wear resistance. Bearings and housings are selected or machined to support radial and axial loads. Hydraulic cylinders, servo motors, and gearboxes are integrated for roll adjustment and material feed control. For CNC machines, motion controllers and software are added to automate roll positions and feedback loops. Finally, the machine undergoes alignment, test rolling with calibration plates, and quality checks to ensure radius accuracy and load capacity.

Applications of Roll benders?

The real-world applications of roll benders span multiple industries. In construction and architecture, they produce curved panels, canopies, and cladding. In energy and heavy industries, roll benders form pressure vessel shells, boiler drums, and pipeline components. Shipyards use them for hull plating and tank sections. Automotive and transport sectors rely on roll forming for parts like exhaust components or chassis sections. In infrastructure, roll-bent guardrails, lamp posts, and bridge elements are common. Even creative sectors—furniture, sculpture, and set design—use smaller roll benders to create seamless, elegant metal curves.

How to choose the right Roll bender?

Selecting the correct roll bender depends on material type, thickness, desired curvature, and production volume. For thin sheets, a standard three-roll machine may suffice, while thicker plates require four-roll or CNC models. Tubular work often needs a mandrel-equipped roll bender to prevent deformation. Evaluate automation level: manual machines suit low-volume work, while hydraulic or CNC units are better for precision and high throughput. Also, consider maximum roll diameter, bending length, and adjustability to ensure the machine meets both current and future production needs.

Maintenance tips for Roll benders?

Proper maintenance extends the life and performance of roll benders. Regularly lubricate bearings, gears, and moving parts according to manufacturer guidelines. Check roll alignment and adjust as needed to maintain accurate bending radii. Inspect hydraulic systems for leaks and monitor fluid levels. Keep the machine clean and free of metal debris. For CNC units, perform software updates and calibrations periodically. Routine inspection and preventive maintenance not only prevent costly downtime but also ensure consistent quality in all roll-bending operations.