Profile Bending Machines are advanced metalworking tools designed to precisely bend structural profiles into curves and complex shapes with efficiency and accuracy, section bending, metal bending equipment, industrial bending machines.

Profile bending machines are essential tools in the metalworking industry, allowing manufacturers and fabricators to bend metal profiles such as beams, angles, channels, pipes, and tubes into precise curves and shapes. These machines are widely used in construction, shipbuilding, aerospace, automotive, and architectural projects where strength and accuracy are fundamental. This guide explores in depth what a profile bending machine is, its working principle, main uses, types, benefits, manufacturing process, applications, how to choose the right machine, maintenance tips, and answers to the most frequently asked questions from professionals in the field.

- What is a profile bending machine?

- What is the working principle of profile bending machines?

- Uses of profile bending machines

- Types of profile bending machines

- What are the advantages and benefits of profile bending machines?

- Manufacturing process of profile bending machines

- Applications of profile bending machines

- How to choose the right profile bending machine?

- Maintenance tips for profile bending machines

- Frequently Asked Questions (FAQ) about profile bending machines

What is a profile bending machine?

A profile bending machine is a piece of industrial equipment designed to bend various types of metal profiles into curved shapes while maintaining the material’s structural integrity. Unlike simple rollers for sheet metal, these machines are specifically engineered to handle structural sections such as H-beams, I-beams, angles, channels, square tubes, round tubes, and even special extrusions. By adjusting the position of the bending rolls and applying controlled pressure, the machine can produce arcs, spirals, and complete circular shapes. These machines are indispensable for industries that require high precision and durability in metal structures, allowing complex geometries that would otherwise be impossible or extremely costly to achieve manually.

What is the working principle of profile bending machines?

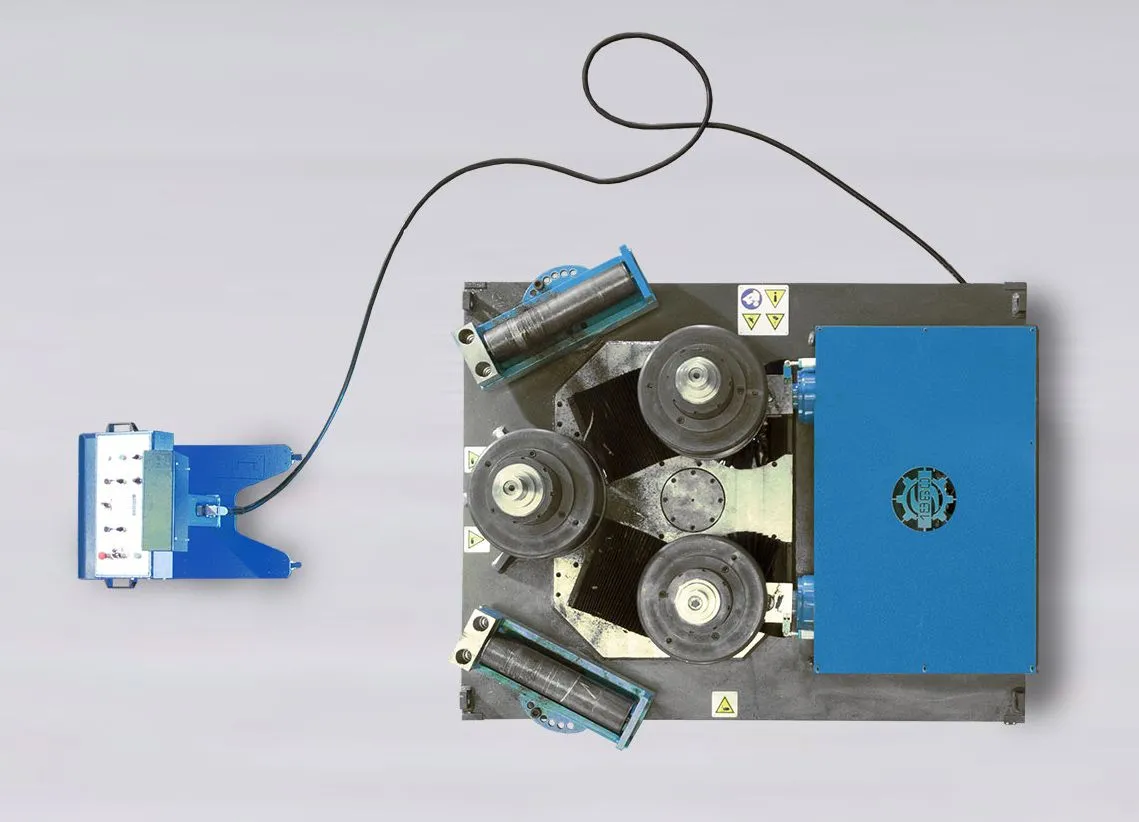

The working principle of profile bending machines is based on the mechanical deformation of the metal profile as it passes through multiple rolls. Typically, three rolls are arranged in a pyramid configuration, where two rolls support the profile from below while the third applies pressure from above, forcing the metal into the desired curvature. Hydraulic or electric systems control the rolls, ensuring uniform bending with minimal deformation. In advanced CNC machines, sensors and software automatically calculate the exact pressure, angle, and positioning, allowing for repeatable accuracy even with complex shapes. This principle ensures that profiles can be bent without compromising strength, avoiding common issues such as flattening, buckling, or twisting of the section.

Uses of profile bending machines

Profile bending machines are highly versatile and are used across multiple industries. In construction, they are employed to fabricate curved beams, arches, and frameworks for modern architecture. In shipbuilding, they bend heavy steel sections required for hulls and decks. The aerospace sector relies on them for lightweight aluminum profiles shaped for aircraft fuselages and structural components. In the automotive industry, they are used to produce roll cages, chassis parts, and exhaust components. These machines are also essential in the energy sector for the production of pipelines, wind turbine towers, and structural supports for solar panels. Their flexibility makes them a cornerstone of both heavy-duty and precision engineering projects.

Types of profile bending machines

There are several types of profile bending machines, each suited to specific tasks. The most common are three-roll bending machines, available in horizontal and vertical configurations, ideal for general-purpose bending. Four-roll machines provide greater control and precision, as the extra roll allows simultaneous clamping and bending. CNC-controlled machines are the most advanced, capable of handling complex geometries with high accuracy and repeatability. Smaller manual machines are suitable for light work or workshop use, while large hydraulic versions are designed for heavy-duty bending of thick steel beams. Specialized models exist for bending pipes, tubes, or even custom extrusions, ensuring that every industry can find a machine tailored to its specific needs.

What are the advantages and benefits of profile bending machines?

Profile bending machines offer numerous benefits that make them indispensable. They increase efficiency by reducing the need for welding or cutting to create curved shapes. They ensure consistency, delivering repeatable results across multiple production runs. Advanced machines with CNC technology minimize errors and material waste, lowering production costs. Another advantage is their versatility, as they can work with a wide range of materials including steel, aluminum, copper, and stainless steel. Moreover, they enhance design possibilities, enabling architects and engineers to create innovative structures with complex curves. By maintaining the strength of the profiles during bending, these machines also guarantee the durability and safety of the final product.

Manufacturing process of profile bending machines

The manufacturing process of profile bending machines combines robust engineering with precise assembly. The machine frames are built with high-strength steel to resist heavy loads. The bending rolls are made from alloyed, heat-treated steel for durability and wear resistance. Hydraulic systems, motors, and electronic controllers are integrated to ensure smooth and precise operation. Quality control tests include load testing, alignment checks, and safety inspections to guarantee performance and reliability. Many manufacturers also equip their machines with user-friendly interfaces and safety features such as emergency stops, overload protection, and guarding systems. The result is a robust machine capable of continuous use in demanding industrial environments.

Applications of profile bending machines

Profile bending machines have applications in almost every industry that uses metal structures. In civil engineering and construction, they are used for bridges, stadiums, and architectural facades. In transport, they contribute to the production of railway carriages, ship structures, and aircraft frames. The renewable energy sector uses them to build wind turbine supports and solar panel frames. Smaller workshops use them for decorative metalwork, gates, and artistic installations. Their ability to handle both small-scale and large-scale projects makes them versatile tools, bridging the gap between craftsmanship and industrial production while ensuring precision, safety, and efficiency.

How to choose the right profile bending machine?

Choosing the right profile bending machine depends on several factors. The type of material and its thickness are critical, as machines are rated for specific capacities. The desired bending radius and shape complexity also influence the selection. For small-scale or occasional use, a manual or semi-hydraulic machine may suffice, while for industrial-scale operations, a CNC-controlled hydraulic machine is more appropriate. Other aspects to consider include the size of the profiles, the frequency of use, available workshop space, and budget. It is also important to assess the availability of technical support, spare parts, and training from the manufacturer to ensure long-term productivity and safety.

Maintenance tips for profile bending machines

Proper maintenance is essential to keep profile bending machines operating efficiently. Regular lubrication of moving parts helps reduce wear and prolongs service life. The rolls should be inspected frequently to ensure they remain free of surface damage that could affect bending quality. Hydraulic systems need regular checks for leaks and pressure calibration. Electrical and CNC systems should be tested for proper functioning and updated when necessary. Cleaning the machine after each use, removing dust and metal shavings, helps maintain smooth operation. Following the maintenance guidelines provided by the manufacturer ensures reliability, minimizes downtime, and extends the overall life of the machine.

Frequently Asked Questions (FAQ) about profile bending machines

Can profile bending machines bend stainless steel?

Yes, most profile bending machines can bend stainless steel, provided the machine’s capacity matches the profile’s thickness and hardness. Specialized rolls may be required for certain grades to avoid surface damage.

What is the difference between a three-roll and a four-roll machine?

A three-roll machine typically requires repositioning of the profile for pre-bending, while a four-roll machine allows clamping and bending in a single pass, offering higher precision and efficiency.

Are CNC profile bending machines worth the investment?

For companies that require high precision, repeatability, and large-scale production, CNC machines are a valuable investment. They reduce human error, save time, and ensure consistent quality across multiple runs.

Can profile bending machines produce spiral shapes?

Yes, advanced profile bending machines can be configured to produce spirals, helices, and other complex geometries, which are often required in architectural and industrial applications.

How long does a profile bending machine last?

With proper care and regular maintenance, a profile bending machine can last several decades. Durability depends on build quality, intensity of use, and adherence to recommended service schedules.