Dishing and Flanging Machines Explained: Complete Metal Forming Guide, Benefits, Process & Applications

Dishing and flanging are essential metal forming processes used to shape flat steel plates into curved heads and flanged rims for pressure vessels, tanks, boilers, and industrial components. These operations combine precision engineering and mechanical forming to create high-strength, geometrically accurate parts required in energy, chemical, food, and marine industries. In this complete guide, you’ll learn what dishing and flanging are, how they work, their advantages, manufacturing steps, key applications, and expert advice on choosing and maintaining the right equipment for your production line.

- What is a dishing and flanging?

- What is the working principle of dishing and flanging?

- Uses of dishing and flanging?

- Types of dishing and flanging?

- What are the advantages and benefits of dishing and flanging?

- Manufacturing Process of dishing and flanging?

- Applications of dishing and flanging?

- How to choose the right dishing and flanging?

- Maintenance tips for dishing and flanging?

- Frequently Asked Questions (FAQ) about dishing and flanging

What is a dishing and flanging?

Dishing and flanging are paired sheet-metal forming operations used to produce curved heads and their mating rims. “Dishing” transforms a flat plate into a shallow dome—spherical, torispherical, ellipsoidal, conical, or custom radii—by plastic deformation under press, spinning, or incremental forming. “Flanging” then bends the perimeter to create a consistent lip (outward or inward) that aligns, locates, and strengthens the joint to a cylinder or another shell. Treating the two steps as a coordinated workflow ensures geometry continuity from crown to edge, controls thickness distribution, and prepares a weld-ready interface. In practice, fabricators specify dish profile, knuckle radius, crown radius, and flange height/angle to meet codes, fit-up, and end-use loads. From tank heads and pressure ends to architectural domes, the term often appears as a single capability because plants that do one almost always do the other to deliver a complete, ready-to-join component.

What is the working principle of dishing and flanging?

The physics center on controlled plastic flow. During dishing, normal pressure and friction guide metal from the plate’s mid-span toward the rim, stretching the crown while compressing or drawing material near the knuckle depending on the method. Toolpaths, die radii, blank size, and lubrication balance strain to avoid wrinkling and tearing. Flanging then imposes localized bending around a defined radius; edge fibers see tension (stretch flanging) or compression (shrink flanging). Because springback relaxes angles after unloading, machines intentionally over-bend and compensate via CNC feedback or proven set-ups. Successful runs keep equivalent plastic strain within the material’s formability window, maintain minimum thickness at critical zones, and achieve tight runout on flange height and squareness so the head fits the shell with minimal heat-input correction at welding.

Uses of dishing and flanging?

The paired processes are indispensable wherever a curved closure must join a shell cleanly and safely. Fabricators use them to make heads for atmospheric and pressurized tanks, boiler ends, separators, filters, heat-exchanger covers, manways, and drums. Beyond process industries, they appear in naval and rail vessels, silo roofs, mixer bowls, vacuum chambers, food and pharma tanks, water heaters, fire-suppression cylinders, and even architectural features. The strategic value is repeatability at scale: starting with commodity plate, a shop can produce standardized head geometries and flange details that match common shell diameters, simplifying procurement, fit-up, and repairs. Because the flange provides a robust welding land and alignment reference, downstream assembly times shrink and joint quality becomes more predictable across shifts and lots.

Types of dishing and flanging?

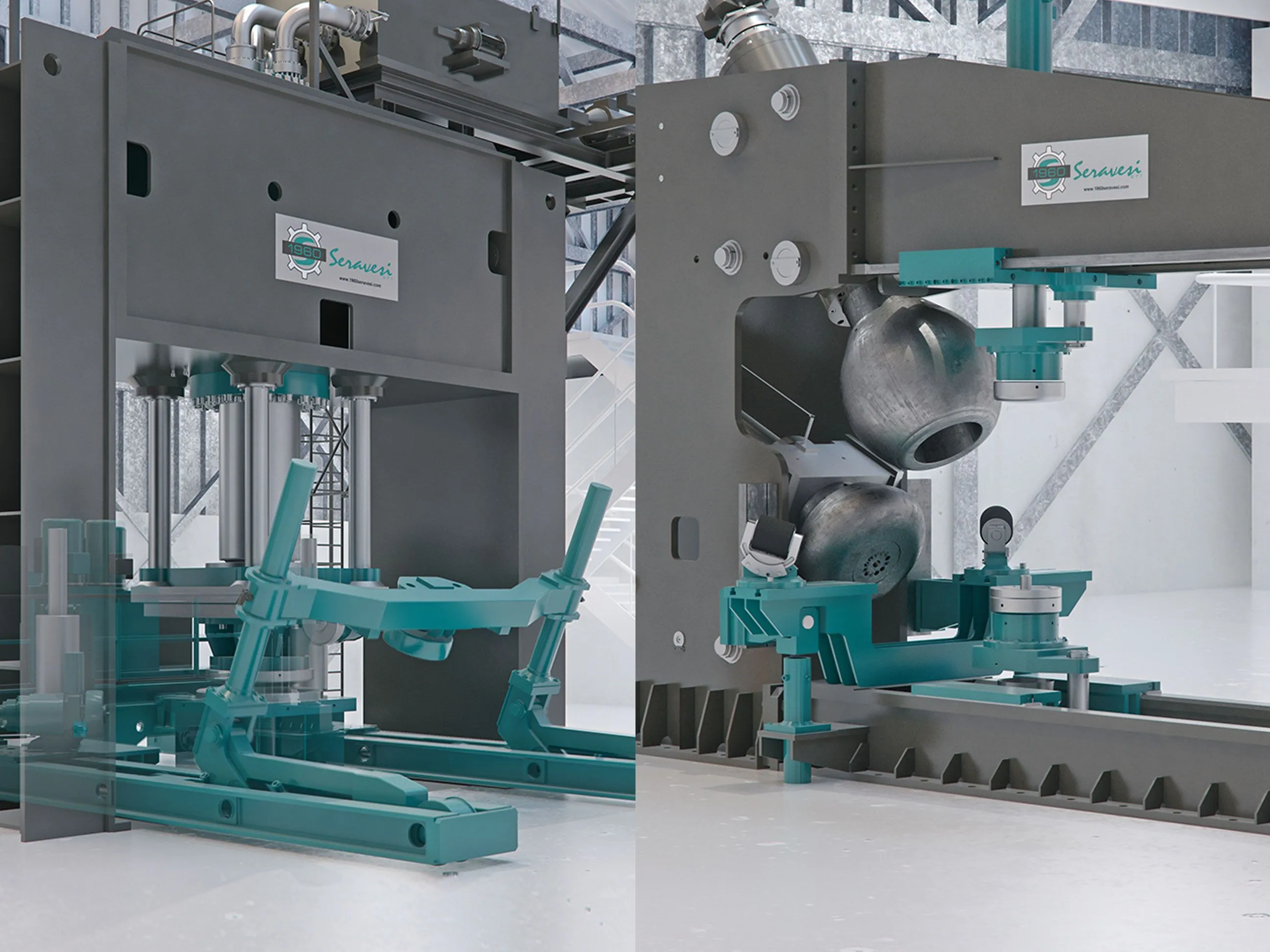

“Types” can describe final shapes, forming approaches, or flange modes. On shapes: spherical, torispherical, semi-elliptical, ellipsoidal, shallow cone, and flat heads with a formed knuckle are the staples, each trading off depth, volume, and stress distribution. On forming approaches: single-stroke press forming, multi-hit pressing, spinning, hammering/incremental forming, and hybrid press-plus-roll methods are common. On flange modes: outward, inward, stretch, shrink, roll-flanged, and joggled/offset rims serve different joint styles. Machine configurations range from dedicated hydraulic dishing presses with toolsets for each radius, to combo dishing-flanging lines with programmable rollers and measuring arms. Choosing among these “types” hinges on diameter range, thickness, alloy family, tolerance, and takt time.

What are the advantages and benefits of dishing and flanging?

Pairing the operations streamlines fabrication: one flow from plate to weld-ready head reduces handling, fixtures, and changeovers. Precision tooling and CNC motion hold crown radius, knuckle radius, and flange height to tight bands, improving circularity and shell-to-head alignment, which in turn lowers weld distortion and rework. Material yield improves because blanks are optimized to the target geometry and thinning is controlled; fewer scrapped parts offset tooling cost. The flange adds stiffness for transport and welding, provides a consistent land for NDE, and can be tailored (offsets, bevel allowances) to the shop’s preferred weld prep. With automation, shops capture data for traceability—press loads, strokes, angles—supporting code compliance and continuous improvement.

Manufacturing Process of dishing and flanging?

Production starts with material selection and blanking: grade, heat, thickness, and diameter align with design code and corrosion allowances. Edges are deburred and marked for orientation. Dishing proceeds by pressing or spinning the plate into the die path, typically in staged hits to distribute strain; operators verify crown depth, chord measurements, and knuckle radius after each pass. Once the profile is within tolerance, the workpiece moves to the flanging machine, where programmable rolls or forming arms bend the rim to the specified height and angle. After flanging, trimming ensures a clean, concentric edge; bevels or offsets are added as required. Final steps include dimensional inspection, thickness mapping at critical zones, surface prep, and documentation of parameters for quality records before welding or shipment.

Applications of dishing and flanging?

Core applications include storage tanks for water, fuels, and chemicals; pressure vessels for steam, air, and process media; heat-exchanger covers and bonnet ends; cryogenic tanks; food-grade and pharmaceutical reactors; and firefighting cylinders. Power generation uses dished ends in boilers and condensers; marine and offshore rely on them for robustness and serviceability; mining and agriculture use large-diameter heads in silos and mixers. In HVAC and building services, elliptical and torispherical heads compactly cap vessels in tight mechanical rooms. Because geometries can be standardized, spare parts inventory is simplified across fleets of equipment, enabling faster turnaround in shutdowns and turnarounds.

How to choose the right dishing and flanging?

Match capability to need. Define diameter range, thickness window, alloys, and target head profiles, then shortlist machines that meet required tonnage, die clearance, and flange height/angle accuracy. Evaluate control sophistication—teach modes, angle feedback, and automatic compensation for springback—plus tool change times and guarding. Check vendor support, spares availability, and training. For high-mix/low-volume work, flexibility (quick tooling swaps, broad radius library) beats peak speed; for standardized SKUs, integrated dishing-flanging lines with automated gauging maximize takt and repeatability. Don’t neglect downstream fit-up: ensure flange tolerances, bevel allowances, and offsets suit your welding procedures and NDE plans. Finally, compare lifecycle cost: energy, maintenance, scrap, and throughput—not just purchase price.

Maintenance tips for dishing and flanging?

Adopt preventive routines anchored in measurement. Inspect dies, rolls, and knuckle tools for wear, scoring, and micro-cracks; polish or replace before defects propagate to parts. Calibrate hydraulic pressures, position sensors, and angle encoders; verify springback compensation against gauge blocks. Keep hydraulics clean and leak-free, change filters on schedule, and maintain proper lubricant film on sliding interfaces. Track part metrics—thickness at crown/knuckle, flange squareness, runout—and trend them to detect drift early. Train operators on defect recognition (edge splits, wrinkling, orange peel) and safe recovery procedures. Document every batch with loads, strokes, and angles to speed troubleshooting and to satisfy audits under applicable codes.

Frequently Asked Questions (FAQ) about dishing and flanging

Q1. Can any thickness be formed?

A. Practical limits depend on alloy, diameter, and machine tonnage; extremely thin plates risk wrinkling, very thick plates need heavy presses and generous radii.

Q2. Do I always need a flange?

A. No—some heads weld without a formed rim—but flanges improve alignment, stiffness, and weld quality.

Q3. What defects occur?

A. Thinning, edge splits, wrinkling, and springback; mitigation comes from tooling condition and staged forming.

Q4. Is automation worthwhile?

A. Yes: it stabilizes quality and captures process data.

Q5. When to replace tooling?

A. When dimensional drift, visible wear, or rising scrap appear—don’t wait for catastrophic failure.